Quality Control

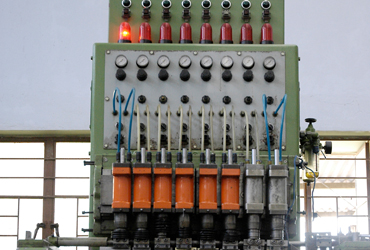

The company has all the basic facilities required for manufacturing Rollers, Like Annealing, Forging, Tumbling, Heat treatment, Shot blasting, Grinding, Super finishing and Testing.

Sophisticated processing technology highly dedicated well experienced staff and personnel training, continuous inspection and documentation of the process ensure consistent high production, quality and performance.

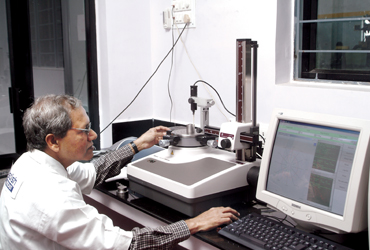

All raw materials are tested for its Chemical Composition by Spectro Photo meter and Micro Structure is checked by qualified metallurgist before and after heat treatment.

Surface roughness and roundness are measured with sophisticated roughness tester and roundness tester. Statical records are maintained as per ISO and IATF 16949 Standards. The company is an ISO 9001 : 2015 Company certified by TUV.

Visual inspection is performed by specially trained staff and every roller is 100 percent visually inspected.

Manufacturing process adopted is as accepted by established internationally reputed Bearing Manufactures.

We also have a well stocked, well managed store, capable to quickly cater all our customers requirement at very competitive price with suitable certification.

In order to achieve optimum quality standards in our products, we put tremendous efforts on continuous improvement of our manufacturing processes, testing methods and quality control.

Our growing customer base places upon us the requirement for a high level flexibility.

© Copyright 2018. All Rights Reserved.

Developed By: TrueDesign